Introduction: Custom Airsoft AK 47 Repair/Fix (Fallout 4 Inspired)

Welcome all! This Instructable is a little different to my usual replica builds for this project is a repair job that draws inspiration from its source material; my choice is none other than the post-apocalyptic world of Fallout 4, and in Fallout 4 (Nuka World DLC) is the wonderfully unique Splattercannon! A widely customizable AK 47 with an amazing paint scheme! (not to mention the shovel you can have as a stock!)

The source material is influencing both design and function, sourcing both spare (and scrap) parts from an airsoft AK 47, fixing it up with stuff I already have and common hardware parts, and finishing it in the cheapest manner possible, apocalypse style! I won'tbe replicating the Splattercannon directly, rather I'm using similar elements, like the colour and short size of the gun.

This tutorial is widely varied for each application and relies on the ability to work around what you have and what you can do with materials and tools. Use your strengths!

Step 1: The Plan, the Gun, and the Components

This build is going to use a mix of AK parts I have gathered over the years from modding other Airsoft AKs as well as additional parts to make up a complete gun. The plan is to build this as cheaply as possible and still have it perform smoothly; This isn't going to be a precision high-end machine, but it'll be good enough to have a ton of fun with!

I will be building an AEG, (Airsoft Electric Gun) the most common and the most popular choice among airsofters for their reliability and ease of use.

The steps we need to cover for this build are: the gearbox (the most important component for any AEG), the inner barrel, the stock, the front end and the selector switch. All of these components are either broken or not on hand and must be fixed to make the gun functional; everything after that is optional such as paint or accessories.

Other than the airsoft parts themselves, tools and materials can vary for each build but having tools such as a Dremel with a few attachments, a hacksaw, a drill, sandpaper, a screwdriver set, a set of files and a selection of adhesives and putty will cover most, if not all requirements for modification.

Step 2: The Gearbox and Motor

The gearbox is like an engine for AEGs, so to speak and much like a car's engine, an AEG will not run unless it's completely functional. I bought this gearbox on eBay for spare parts a long time ago but I decided this would be perfect for this project to rebuild it.

In airsoft, AKs use a 'Version 3' style gearbox that uses version 3 parts respectively. These are widely available and are easily upgradable, plus cheap parts can be sourced with a little searching and do the job well enough.

Fortunately my internals were all more or less in good shape, however a few areas needed some work to run properly. I loosened the trigger contacts so the current flows through the gearbox and the trigger doesn't lock up. The gears were re-shimmed so they would run smoothly. The selector switch was replaced and lastly, I picked up a cheap motor cage and replaced the broken half of the original. All this results in a working gearbox!

Note: Gearbox's are fairly daunting and a whole Instructable could be written on just explaining how the components work. I highly recommend doing external research if you need to mess around with your gearbox and you haven't done so before.

Step 3: The Body

Now with the pesky gearbox out of the way, it's time for the fun stuff!

The original colour of the body is actually green (I painted it black a loooong time ago) and as the Splattercannon has a colourful paint job, I sanded off all of the black to reveal the native green.

I have no stock to mount to the back, so we are gonna make it stockless! Using a broken stock mount for the body that I modified for a different build, I applied Milliput around the mount to make it flush and I glued on a piece of 3mm scrap acrylic to the back of the body (after filing the back flat) so the mount would sit flush.

Before blending the pieces, it made sense to permanently bond them together, (typically the original piece was meant to be removable for other attachments) I used the cheapest 2 part Epoxy I could find (keeping in theme!) to bond them together.

A layer of body filler blends and caps off the back and sandpaper smoothes it into a uniform shape. When the paint is applied, it will look just like it's part of the body.

Step 4: The Front Receiver and Outer Barrel

The outer barrel and its attachments have no proper mounting point to the front receiver, so we'll have to improvise and modify the front receiver to... well, receive the barrel.

I used a Dremel with a sanding drum to rout out a channel to adapt the broken ended gas block; it sits in about 8mm.

With this new configuration, the outer barrel is way too long and needs cutting down at the back. A miter box and a hacksaw does the job in a flash.

A new hole is drilled (4.5mm) to adapt the pin that secures the barrel to the receiver because we just cut off the end of the barrel that had the original hole.

With the barrel locked in place, a piece of hex tube (from the original gun) is cut to length and Sugru'd to the receiver; the gas block has a convenient hex channel in it that will lock into the tube, and with that the front end is now shorter and extremely secure to the receiver!

Step 5: The Inner Barrel

All airsoft guns have a hop-up unit that connects the gearbox, magazine and barrel and right now, I don't have a barrel. Buying an airsoft inner barrel is veeeery expensive and I don't wanna spend much money at all... so we're gonna make one for a fraction of the price!

I bought some 6mm Inner Diameter (8mm OD) aluminium tube from the hardware store and cut the barrel to length (210mm). A small bur is left on both sides of the tube after cutting, these are cleaned up with wet and dry sandpaper and a cone shaped grinding stone on the dremel is used to lightly countersink the ends of the tube; this helps the BB feed into the chamber better.

To adapt the barrel to the hop-up, 2 grooves and a channel need cutting into the tube. Most if not all hop-up units accept the same style of barrel for AEGs although I always advise doing your research first on the part just to be sure ;)

I used a square needle file and carefully grinded away material to open a small channel and cleaned it up with wet and dry sandpaper. The same technique was used to file notches on the sides to adapt the hop-up clip.

I also filed a groove with a triangular file on the bottom to help align and guide the barrel to the hop-up. All of this allows the hop-up bucking (the rubber part) to sit flush over the barrel which is extremely important for the gun to cycle optimally.

Note: This homemade barrel isn't gonna match up to a precision airsoft inner barrel but like I mentioned, I'm just building a gun I can have fun with that works and this certainly works!

Step 6: Paint/Prep

All the pieces I wanted/needed to address are complete, now I can paint this bad boy. I broke the components down into 2 categories; the metal parts will get a pink enamel coat and the plastic parts will get an acrylic blue coat.

To prep the paint, all pieces are wet sanded down to remove paint, grease and scratches. On a few metal pieces I filed off excess JB-Weld from a previous build (it looks ugly as hell when painted over!)

Typically I would be meticulous with getting a perfectly smooth finish (I would also usually use primer to promote paint bond) but since I'm sticking to the scrap/cheap approach I'm not gonna focus on it :) If you want to ensure a perfect surface, spending more time on cleanup and applying spray primer will be the way to go.

I gave the metal parts 3-4 LIGHT coats of pink enamel (enamel takes AGES to harden and dry) and 2-3 coats of blue for the plastic parts. Let the paint sit for at least 24 hours.

I have this rail mount for AK AEG's that I will never use for any other gun so I'm throwing that into the mix as well. It's prepped and painted the same way.

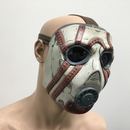

Step 7: Weathering!

The paint is dry and lookin' fresh, now it's time to go to town and remove it! What we're gonna do is simulate wear and tear by scuffing edges where paint would come off over time; this is a popular technique among prop makers to make stuff look old and well used.

Since the Fallout universe is set in the post-apocalyptic future, most equipment is heavily scuffed and worn (maintenance isn't high priority in the world of Fallout) so we'll do the same.

Using sandpaper to hit the edges, the pink paint is lifted, revealing the silver glimmer that raw metal has. This breaks up the solid colour of the gun and makes it look much more used in. This technique is very fun and easy, however being selective with your scuffs is key to making it look good; don't get carried away!

For the body I did the same sanding technique, revealing the green underneath the blue for an interesting contrast, simulating the multicolour appearance that the Splattercannon has.

Step 8: Assemble!

All of the pieces are ready; it's time to assemble!

The leaf sight is connected to the front end first, followed by the outer barrel that has the front sight and gas block screwed in. The pin locks the barrel and all of the receiver screws are inserted. The hop-up unit screws into the end of the receiver with 2 screws and the barrel feeds through to the front sight.

The body gets the trigger guard screwed in first followed by the gearbox. The gearbox slots in place and is secured with the selector switch screw and the grip screw. The front end slides into the body and 4 screws lock it into place.

The battery cover (also holds the charging handle) slides and locks over the gearbox with only a single screw and the top cover slides on top. the battery sits on top of the body and connects with the mini tamiya connector that stick out of the front end.

The last thing to add is a small metal nub that rests under the selector plate. This stops the selector plate from sliding past semi-auto. I drilled a 3mm hole and superglued that sucker in.

Step 9: Complete!

The gun is done! I slapped on the rail mount, painted the grip blue and grabbed a mag and this baby is ready to roll! Using existing and scrap parts to build a functional project is something I've wanted to try out for a long time and I'm very pleased with the result.

It was a lot of fun working with existing parts and fixing up broken parts to work again and the best part is, it works better than I expected! It has a surprisingly accurate range of 35-40 metres, a decent fire rate and best of all, it doesn't skip any BBs! I'm amazed by the homemade barrel most of all.

All in all I only had to buy a selector switch set, a motor cage, a 6mm aluminium tube, a tube of £1 epoxy and a new battery; the rest was either refashioned or simply fixed. This project only costed me ~£35 and £15 of that was the battery!

I hope you like this Instructable and if you'd like to see more of this kind of stuff let me know! And if you build your own or have comments about details then feel free to share :)

![Gameboy Advance: Tingle Tuner [Wind Waker]](https://content.instructables.com/FR5/T76P/KCF3U75R/FR5T76PKCF3U75R.png?auto=webp&crop=1%3A1&frame=1&width=130)