Introduction: Make a Glass Bottle Scoring Jig - Teardown

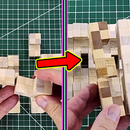

This instructable is going to be a bit different format than my others. Instead of making a jig from scratch, I'm going to be taking this jig apart. Then as I'm putting it back together I'll walk through the steps I took when I made it. What you see in the pictures may be a bit confusing compared to what I'm describing, since I'm using wood that already has all the cuts made and holes drilled. But I'll do my best describing the steps. Eventually I'll have a better design, which I'll show how to build as I make it.

If you prefer to view this instructable in video form, you can watch it here: https://youtu.be/qRf38Rg-Nlg

If you want to learn how to cut bottles, check out one of my other instructables:

Bottle-Cutting-With-a-Soldering-Iron

Tools Needed:

- Saw (jig saw or hand saw)

- Drill

- Long 1/4 Inch Drill Bit

- Long 1/8 Inch Drill Bit

- Hammer

- 3/8 Inch Drill Bit (optional)

Parts Needed:

- 2x4, at least 40 inches long

- 1 - 6 Inch Bolt, 1/4 x 20 tpi

- 2 - Wing Nuts (that fit the bolt)

- 3 - Fender Washers

- 1 - Cone Shaped Piece Of Wood

- 1 - 1/2 Inch Bolt, 1/4 x 20 tpi

- 1 - 1 Inch Coupling Nut (that fits the bolt)

- 10 - 6 Inch Wood Screws

- 6 - 1 1/2 Inch Wood Screws

- 1 - Glass Cutter

- 2 - 2 Inch Wheels

- 12 - Threaded Inserts (optional)

Step 1: Cut the Boards

I took a 2x4 and cut it into 3 pieces; 2 at 15 inches and one at 10 inches. I put the two 15 inch pieces next to each other, then held the 10 inch piece on it, where I wanted it to go. I traced lines around the 3 sides of it so I could see where I needed to cut the 15 inch pieces. After removing those pieces I cut, I checked to make sure the 10 inch piece fit. It's not a perfect fit, but I figured it would be close enough.

Next I needed to cut out a slot in the 10 inch piece. Measuring down from the top, I drilled a hole at 2 1/2 inches and 6 3/4 inches. Using a long 1/4 inch drill bit, I drilled several holes between those two points. Then using a chisel I removed the rest of the wood between there. It took some time and I worked at it from both sides of the board.

Step 2: Assemble the Bottle Pivot

Next I assembled the bottle pivot into the slot I just made. I used a 6 inch long, 1/4 inch 20 tpi bolt, 2 wing nuts, and 2 fender washers. I put 1 wing nut on the bolt first, making sure I put it on the correct way, then one of the washers. Then I put the bolt through the slot, added the other washer, then the other wing nut.

This setup lets you control the vertical and the horizontal of the pivot point. Twisting the 2 wing nuts towards each other holds it tight in place.

The pivot point needs to be a wooden piece that's tapered. I used a drawer handle that I put a hole through. In hind sight, it would have been easier to make a hole slightly smaller than the 1/4 inch bolt and just thread it onto the bolt, but I over complicated it. Instead of drilling a hole that goes half way through this piece, I drilled one that goes all the way through. Then I put a smaller bolt through it. Because of this I had to add a coupling nut onto the 6 inch bolt so that I could connect it the the smaller bolt that I put into the wooden piece.

Step 3: Install the Wheel Mounts (Optional)

Before I attach the two 15 inch boards together, I'll explain the big holes you see. Those are for mounting the wheels. I measured the distance between the mounting holes on the wheels, marked out on the boards where I need the holes drilled, and used a 3/8 inch drill bit for the holes. That's the size I needed for the threaded inserts I used. This lets me move the wheels as I need to. In the end, I realized that I only needed to use the outer holes for securing the wheels, and I never ending up needing the inner holes for anything. The threaded inserts go into the holes. They don't push in easily, so I used a hammer to pound them in.

If I were to do over again, I would not use this method for mounting the wheels. Instead of drilling those holes and installing those threaded inserts, I would just use wood screws. I think it would be just as effective, and be MUCH less work.

Step 4: Bolt the Horizontal Boards Together

Next we'll drill some pilot holes for the screws that will hold the boards together. In the picture, you can see from the inner edge there are twice as many holes as there are on the outer edge. This is because I didn't want screws that go all the way through the boards. It's also important that the holes from each side are staggered so that they don't collide with each other.

I used a long 1/8 inch drill bit to drill these pilot holes. The screws I used are 6 inch heavy duty deck screws. If you decide to use the threaded inserts, make sure these screws don't collide with them. I drilled 5 holes in each board, for a total of 10 screws. 4 of the 10 will also go through the 10 inch board before I'm done.

In one of the boards I used 3 of the screws. Since they are so big, it's difficult to get them in so I used my drill with a socket to get them in. I only put them in far enough that the tip is poking out of the other side. I line it up with the other board, then tap it with a hammer. This marks where the holes need to line up, so now I know where I need to drill the other side of the pilot holes for these first 3 screws.

I measure how much deeper the screws need to go, and put some tape on the bit a little deeper than that point. Then I compare it with the screw, just to double check. Then I drill those other 3 holes at the points where the marks were at. I put the boards together, and finished driving the screws in. Again, I use my drill for this, making sure the pilot holes are lined up with the screws.

The other side needs the pilot holes drilled deeper, so I move the tape on the bit to match the full length of the screws. Then I drill these 3 pilot holes the rest of the depth that they need to go. Now these other screws are ready to be put in the boards.

Step 5: Bolt the Vertical Board Into Place

I grab the 10 inch board and hold it in position. Then I drill 2 of the pilot holes from one side. Doing this is awkward, and would be much easier if I had 3 or 4 hands to hold everything with. Once these pilot holes are drilled, I put in the 2 screws. Then I do the same thing with the last 2 holes on the other side. And with that, the hardest parts are done and we are almost finished.

Step 6: Mount the Cutting Block

I grab the 2 scraps that I cut from the 15 inch boards. On one of them I put 3 pilot holes for regular wood screws. One of the screws I want in about the middle, and the other 2 screws I want on either end. I tighten those 3 screws down by hand, then I grab the other piece of scrap wood. I want one screw towards the top, but I need to keep in mind where the previous screws are, so that they don't collide.

I grab my glass cutting tool, and hold it in position where I want it. I use a chisel to carve out a little groove in this wood, to help hold it in place. Then I made holes for screws to go on each side of the glass cutter. Notice that I have extra holes, because I tried a few different positions. The screw that I put on the right side I do not screw down all the way, but I still want it deep enough to go into the lower piece of wood. I also want the head of this screw to be up against the glass cutter. Then for the other side I use a washer with the screw. This one I get it tight because it's going to be the main one holding the glass cutter from moving.

Step 7: Mount the Wheels

Now it's time to mount the wheels. This part is pretty straight forward. Just put the wheels where you want them and bolt them down. If you decided to NOT use the threaded inserts, Just use wood screws to mount the wheels.

Now that my jig is all put together, I'll explain briefly how to use it.

Step 8: Brief Use Instructions

Grab your bottle and put it up to the pivot point. Decide if you need to move it up or down. Then decide if you need to move it in or out.

I've moved it in as far as it will go, but it still isn't lining up with where I want to cut this bottle. I can move the cutting block out a bit to give me more room to work with. It will then probably be a bit too far the other way, so be ready to move the pivot back out a bit.

The new position looks better, but there is too much play by the wheels. That means I need to move the pivot up just a little bit more. Sometimes it takes a while to get it positioned just right, but once it's good, you are ready to score the bottle. As you rotate the bottle, hold it down firmly, and push it into the pivot. Always keep a firm grip on the bottle with at least one hand.

Step 9: And That's It!

The jig is up... and ready to use. There are some changes I would make to the design, and I tried to mention those in this instructable. But even without those changes, this design has worked great for me. Feel free to leave a comment, suggesting any changes that would make the design even better!

If you want to see the video version of this instructable, you can watch it here: https://youtu.be/qRf38Rg-Nlg

If you want to see my instructables on cutting bottles, check them out here:

Bottle-Cutting-With-a-Soldering-IronCutting-Odd-Shaped-Bottles