Introduction: Pier 9 Resource: DMS Certification Part I: 3D CAM in Fusion 360

This Instructable is for Workshop Users at Pier 9, or anyone who wants to learn:

-CAM (Computer Aided Manufacturing) in Fusion 360

-Toolpathing for 3D components with a flip

-CNC machining in wood

This Instructable is a detailed, step-by-step set of instructions to show you how to program the toolpaths to machine a wooden serving spoon. At Pier 9, this spoon is the certification part for the DMS 5-axis router, meaning that you must complete this project after taking the DMS Safety/Basic Use course in order to be checked off to use the DMS for your own projects.

In this Instructable, you'll use Fusion 360 to program this part from start to finish. You'll learn how to work with multiple setups, build registration systems, create and constrain 3D toolpaths, and post process your file to G-code. Afterwards, you'll learn how to machine it yourself with the next Instructable in this series: DMS Certification Part II: Machining.

This Instructable assumes no previous experience with 3D toolpathing. The 3D model will also be provided for you. It's important, however, that you have a fundamental understanding of CNC concepts. It's also helpful if you have some experience with 2.5D CAM, which you can gain from this Beginner and Advanced CAM Instructable.

If you want to machine the spoon at Pier 9, you'll need to take:

CNC 1, Concepts of CNC at Pier 9

DMS 5-Axis Router Safety/Basic Use Course

Let's get started!

Step 1: Download Fusion 360

1) Install the free trial of Fusion 360 from the Autodesk website or the Autodesk Education Website.

2) If you are an Autodesk employee, student, or educator, you qualify for the free version of Fusion 360! Follow these steps to activate your educational license.

Step 2: General 3D Machining Workholding Considerations

If you completed the Beginner and Advanced CAM Instructable, you may have noticed that 2.5D CAM only requires a model of the part that you want machined at the end. This is because the part takes the shape of a rectangular prism, which can be held easily inside a vice.

But what do you do when your shape is more organic or irregular, and also must be flipped to machine on both sides? You need additional material that will hold your part inside a vice, against a spoiler board, or flat against the bottom of the machine. It's very hard to program the CAM without having these features incorporated into your model.

In other words, 3D flip machining requires that you model the stock you want left behind, as well as tabs to prevent your part from coming loose inside the machine. These tabs will be cut off and sanded down after machining, usually with a band saw and disk sander.

Note: Another, more advanced, technique for workholding for irregular shapes is making a soft jaw system. You would machine your own custom aluminum jaws to replace the hardened steel jaws on the Kurt vice, and these would hold your part after the flip. No tabs needed.

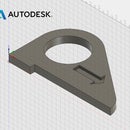

Step 3: Workholding for the Certification Part

For your serving spoon, you will have two tabs--one on each end--and a rectangular prism of stock that will hold the spoon flat after the flip.

When modeling, it's a good idea to make your stock and tabs another body, separate from your part.

The rectangular prisms on either side of the spoon also have three holes, which serve as registration for the flip. More on that in the next step.

Step 4: DMS-specific Considerations

You may have used a Shopbot before, or machined in aluminum on the Haas Mill at Pier 9. When machining on the DMS at Pier 9, CAM and software preparation is similar, but not exactly the same. Here are some important DMS-specific considerations:

-Tool numbering

When you have simulated and finalized your CAM program, make sure that your tools are labeled in the chronological order that they are used. You will learn later in this Instructable how to edit tool numbers.

Remember that the chronological tool numbers in your program do not correspond to the numbers in the DMS tool library drawer. For instance, the fifth tool you use in your program might be the 1" Rough Short End Mill, which is labeled #34 in the DMS library. You will see the DMS library number in the comment for each tool, which will appear in your setup sheet (machining plan). You will learn later how to generate setup sheets.

-Rules for roughing

Machining in wood or plastic on the DMS is not high speed machining (HSM). This means that you can use adaptive toolpaths for roughing, but you cannot use the whole length of the cutter.

When machining wood or plastic, follow the Stepover and Stepdown Rule: The stepover and stepdown should never exceed 50% of the tool diameter.

-Registration system

If you used the Haas before, you're familiar with using a probe to locate your part (the origin of your Work Coordinate System (WCS), also known as Work Home). The DMS, however, does not have a probe. When using the DMS to locate your Work Home, you will insert a tool into the spindle and jog it to the correct location. It's common to trap a piece of paper between the stock and the tool to ensure that Z is correct. In the DMS machine class you will learn how to enter the codes to set your WCS in this way. As you might imagine, this system is not accurate, because you're just eyeballing this location.

This means that if you have a part that requires flip machining, you need to consider how to tackle registration--in other words, how to get the two sides to line up properly with one another. There are lots of options, and they all have advantages/disadvantages based on the specifics of your part. Some common methods include:

--Attaching stops to your spoiler board (waste board) or machine bed

--Machining a contour into your spoiler board, then placing your stock exactly inside that contour

--Drilling holes for dowels that go into the spoiler board--most accurate

This final technique is the the method you will use for the spoon part. After you flip your part, you can insert dowels through the holes and into the spoiler board that will align your part perfectly with your first side.

-Preparing stock

If you're working with solid wood that has not been milled yet, be especially aware that it is not square or flat. Your first toolpath might remove a lot more material on one side of your part than the other. Your workholding, too, might not be as effective if your wood isn't flush to the bottom of the machine. For this reason, it's preferable that you mill your DMS stock ahead of time. At Pier 9, to be checked off to use the joiner and planar you need to take the Advanced Wood class.

If you're working with a laminated material that can't be milled, like plywood, remember that you can still use the table saw or chop saw to get it square after the glue-up.

When installing stock inside the DMS, you can reference a groove in the acrylic machine bed to get your stock as square to the machine as possible--but remember, nothing done "by eye" is ever truly accurate.

Step 5: Open File

Now that you understand the basics, let's get into CAM!

1) Open Fusion 360.

2) In the data panel on the left side, click New Project at the top. Name it "DMS certification part."

3) Download the DMS_spoon_certification_part.ipt file, attached here.

4) In the data panel in Fusion, double click your new project, DMS certification part.

5) Click Upload near the top.

6) Choose Select Files.

7) Select the DMS_spoon_certification_part.ipt file, and click Open.

8) Click Upload.

9) Once the status bar is Complete, click Close.

10) Double click the part in the data panel to open the project.

11) Hide the data panel by pressing the icon near its top right corner--the nine small boxes. It says "Hide Data Panel" when you hover your mouse over it.

12) In the ribbon at the top left, change the workspace to CAM.

13) Orbit the spoon until it is facing up, with the scoop of the spoon closer to you (see screenshot). Do this with the view cube in the top right corner of the screen, by clicking the corner of the view cube where Front, Right, and Bottom intersect.

14) Hovering your mouse over the view cube, right click the icon of the Home and choose Set Current View as Home-Fixed Distance. Now you can get back to this view anytime you press the Home icon.

15) In the CAM feature tree on the left, check that your units are in inches. If not, click the clipboard icon that appears next to the Units, change Unit Type to Inch, and click OK.

Attachments

Step 6: Install Pier 9 DMS Tool Library

1) Download the attached file Feb2017_HSM_DMS.hsmlib (at the bottom of this step).

2) Create a new folder on your hard drive called 'Pier 9 CNC Tool Libraries' and add this file.

3) On the right side of the CAM ribbon, in the Manage Section, click Tool Library. This opens the tool library dialogue.

4) Right click the Local folder and click New Tool Library. This creates a new, empty tool library which we will use to import tools.

5) Type Feb2017_HSM_DMS into the tool library name.

6) Right click Feb2017_HSM_DMS and choose Import Tool Library.

7) Browse to the tool library you just saved on your hard drive and click Open.

8) You should see your new library populate with tools.

9) Click the arrow next to Samples to expand this folder. Make sure all the Sample libraries are unchecked, except the Inch-Aluminum library.

10) Now you can exit this window by clicking the X in the upper right corner.

You just installed the Pier 9 DMS library! You'll find it very useful for programming your parts, because all of these tools have the correct speeds and feeds for machining most materials on the DMS.

Attachments

Step 7: Setup

There are three steps in the CAM process: Setup, Toolpath, & Simulate.

Setup determines the Work Coordinate System (WCS) and the size of your raw material (stock).

1) On the ribbon, click Setup.

In the graphics window, the box surrounding the model contains many nodes. These nodes are potential locations for the WCS origin (Work Home).

2) In the graphics window, click the upper left node.

This moves the WCS to the upper left corner and defines its X, Y, and Z coordinates. Note that the x-axis points along the long axis of the part, the y-axis points away, and the z-axis points up, following the Right Hand Rule. This X, Y, and Z orientation is important and you'll need to remember this when you place your stock in the DMS. For a more detailed explanation of the Work Coordinate System, watch this video: Setting up a Work Coordinate System and read Chapter 4, Coordinate Systems, in the CNC Handbook.

3) With the Setup dialogue still open, click the Stock tab.

4) Change Stock Mode to Fixed size box.

Note that the default width (S), depth (Y), and height (Z) have been determined by the size of your model. These values--20" x 3.5" x 1.5"--are what you want.

5) Click the Post Process tab. Change the program name/number to 100001.

This will be used later, during post processing. For the DMS post processor, your program name MUST be a six-digit number. Do not use programs that begin with number 9--we reserve those numbers for programs that are stored in the controller.

6) Click OK to generate the setup.

Step 8: Create Bounding Box for Adaptive

The next step after Setup is Toolpath.

For 3D parts, always start with roughing toolpaths to remove as much material as efficiently as possible. Then, use finishing toolpaths to remove the rest of the material and meet your design and aesthetic specifications. The best roughing toolpath to use is Adaptive, which is an intelligent toolpath that ensures the forces (load) on the tool remain constant. This allows you to remove material quickly without breaking the cutter.

By default, 3D Adaptive machining will remove all of the stock that surrounds your model. You won't always want the toolpath to do this. For instance, if you're using clamps to hold your part down, you may need to ensure that the tool won't remove the stock near your fixtures. In this case, you want to make sure that the toolpath will only remove material directly around the model of the spoon. To do this, you will draw a bounding box to constrain the geometry of the toolpath. This is a handy trick in 3D machining, and one that comes up frequently.

1) In the ribbon at the left, change the Workspace to Model.

2) Orbit around to the back of the spoon. Hover your mouse over the plane with the two holes in it, and choose Create Sketch.

3) In the ribbon, choose Sketch>Rectangle>2-Point Rectangle.

4) Carefully draw a rectangle that surrounds the spoon, as seen in the image.

5) In the ribbon, chose Stop Sketch.

6) Go back to your isometric view by pressing the Home icon by the view cube. In the browser on the left, expand the Sketches folder. Rename Sketch 1 to "Bounding Box for CAM."

Step 9: 3D Adaptive Roughing

Now, create the 3D Adaptive toolpath.

1) In the ribbon at the top, change the Workspace back to CAM.

2) In the ribbon, choose 3D>Adaptive Clearing.

In the browser, it's a good practice to navigate the tabs from left to right, like reading a book.

3) Click "Select" next to Tool.

4) Choose 1 R0.02" bull nose (1" Bull Nose Rough Short) from the DMS Tool Library. Click OK.

In this case, you're roughing and want to cover a lot of area, so you'll want to choose the biggest diameter tool in the DMS tool library: 1".

5) While still in the Tool tab, set Coolant to Flood.

The DMS does not have coolant, and by default, the tools in the DMS tool library have coolant set to Disabled. However, if you set coolant to Flood, the dust collection system--two spindle-mounted pneumatic intakes connected to the wood shop dust collection system--will automatically close during this toolpath. Close the dust collection whenever possible, to minimize breathing dust particles and make cleanup easier. However, in some cases, like with shorter tools or steeper parts of geometry, the dust collection intakes get in the way and have to be left open (Coolant set to Disabled). Reference two attached images to see how far the dust collection extends below the spindle.

6) Click the Geometry tab--the next tab over next to Tool.

Refrain from pressing "OK" between tabs, because that will generate the toolpath. If you accidentally do, find the toolpath on the left under Setup 1 in the CAM Feature Tree, right click, and choose Edit to go back to the browser.

7) In the geometry tab, next to Machining Boundary, choose Selection.

Notice that the button next to Machining Boundary Selection is now teal blue and says Nothing. This means that you should choose the boundary.

8) Carefully click on the sketch you just drew. It should turn green.

9) Ensure that Tool Containment is "Tool outside boundary."

Hover your mouse over "Tool outside boundary" to see diagrams of the three options in this category: Tool inside boundary, Tool center on boundary, and Tool outside boundary. In this case, you are allowing the tool to go outside the boundary so that it can enter laterally from the sides of the stock; otherwise it would have to ramp into the stock from the top in a helix shape, which is less efficient. You can add an additional offset to this boundary, but you don't need one here.

10) In the browser, uncheck Rest Machining.

Rest stands for "Remaining Stock" machining. This kind of machining will only remove stock that has been left behind by the previous toolpath, and can somtimes make your operation more efficient. However, this is your first toolpath, and making it Rest would add a lot of unnecessary calculation time.

Step 10: 3D Adaptive Roughing Continued

1) Click on the Heights tab. In this tab, you control the upper and lower limits of your toolpath.

2) For the Bottom Height offset, type -0.05.

By default, this toolpath has the Stock top set as the top height, and the Model bottom set as the bottom height. This is close to correct. However, because you will have a spoiler board (scrap material underneath your stock inside the DMS), you can go beyond the model bottom to ensure that you don't leave a thin skin of stock material behind. You just set the bottom of the toolpath to 0.05" below the bottom of the model. The endmill will lightly graze your spoiler board. Check this by viewing the spoon from the side, by clicking on a side on the view cube. You can see the dark blue line, corresponding to the bottom of the toolpath, slightly below the model.

2) Click on the Passes tab. In this tab, you control the behavior of the tool.

3) Change Optimal Load to 0.3.

Hover your mouse over the field next to Optimal Load to see the definition of Optimal load with diagrams. You can think of "amount of engagement" as another way to say stepover. That is, an optimal load of 0.3" = a stepover of 0.3". The CAM software will try to keep this level of engagement as continuous as possible to maintain a constant load, though it may need to go below this number in certain parts of the geometry, such as corners.

Note: If you went through the Beginner and Advanced CAM Instructable, you downloaded a formula for Optimal Load. This formula is for machining in aluminum only. When using the DMS to machine wood and plastic, you'll need to manually set your optimal load.

For machining wood or plastic, follow the Stepover and Stepdown Rule: The stepover and stepdown should never exceed 50% of the tool diameter.

In this case, the tool has a diameter of 1". To be conservative, you set the stepover to 30% of tool diameter, or 0.3".

3) Change Maximum Roughing Stepdown to 0.5.

A stepdown is the depth of each pass in the Z-direction. You have set the maximum stepdown to 50% of the tool diameter, following the Stepover and Stepdown Rule.

Note: For machining metal using HSM (High Speed Machining), you may have learned that you may use the full length of the cutting flutes in adaptive toolpaths. This is correct for metal, but does not apply when machining wood or plastic.

4) Click OK to generate toolpath.

A quick guide to the colors of the toolpath:

Blue = The toolpath itself. The tool moves at the cutting feedrate.

Yellow = Positioning moves. The tool moves at rapid or high speed.

Red = Ramp (helix, zigzag, etc.). This is a way to move the tool down slowly in Z without plunging, which helps preserve the life of the tool.

Green = Lead in/lead out. This is how the tool moves right before or after each cutting move, for a better surface finish.

5) Don't take my word for it! The best way to really learn what any of these terms mean is to try generating the toolpath under that condition, and see what changes. In the CAM Feature tree on the left, right click Adaptive 1, and choose Edit. Then change one thing and re-generate your toolpath by clicking OK. For instance, try "Tool inside boundary" in your Geometry tab. You'll see the helices appear in red (the color assigned to ramps). This shows you why it's useful to allow the tool to go outside the boundary.

6) Restore anything you changed in step 5.

Step 11: Simulate!

After Setup and Toolpath, the next step is Simulate.

After you create any toolpath, you'll want to simulate it to ensure that it's not colliding, that it moves efficiently, and that it's doing what you expect. Pay attention to where and how the tool enters your material, and how much material the tool is removing at any given time.

1) Click Setup 1 in the CAM Feature Tree.

2) In the middle of the ribbon, click Simulate.

3) For Toolpath Mode, choose Tail. This will remove some of the visual clutter from the screen.

3) Click the box next to Stock to view the stock. You can check the box next to Transparent as well--I tend to toggle it on and off, depending on what I'm doing.

4) Press Play at the bottom of the screen.

The slider underneath the Play/Pause controls allows you to speed up and slow down the simulation. Below that is a thin timeline. You can click at any point in the timeline to go to that point. If you hover your mouse over the timeline, it will display the name of the toolpath, the tool number, and estimated machining time.

5) Click Close to exit the simulation.

Step 12: 2D Pocket for Hole Handle

Before you keep going, remove the visibility of the sketch you created for the Adaptive toolpath.

1) In the Ribbon, switch to the Model workspace.

2) Click the light bulb next to Bounding Box for CAM. It should turn off the visibility of this sketch.

3) Switch the workspace back to CAM.

Now, you're going to machine the area inside the hole in the spoon's handle. You will use a 2D toolpath to do this, because the bottom contour of this hole almost lies flat on a 2D plane (the XY plane).

4) In the Ribbon, choose 2D>2D Pocket.

5) Click Select next to Tool, and choose 1/4" Flat (1/4" EM Long) from the DMS Tool Library. Select OK.

6) Leave Coolant set to Disabled.

This is because this tool is relatively short and the toolpath goes fairly deep relative to the top of the stock. You don't want to risk collision between the dust collection system and the stock.

6) Click on the Geometry tab.

7) Zoom in and orbit so you can clearly see the hole in the spoon's handle. Carefully select the bottom edge of this hole.

View the spoon from the side. Note that the blue selection is flat along the XY plane because you are using a 2D toolpath. Your geometry is so close to flat that this doesn't make your toolpath inefficient.

8) Click on the Passes tab. Check the box next to Multiple Depths. This is how you'll ensure that the tool is stepping down, rather than doing the entire toolpath at the bottom depth.

9) Change Maximum Roughing Stepdown to the maximum stepdown allowed. You know what this is. Check your answer against the attached screenshot.

10) Uncheck Stock to Leave. You are treating this Pocket toolpath as a finishing toolpath, so you don't want to leave any stock behind.

11) Click OK to generate the toolpath.

Step 13: 2D Pocket for Hole in Handle Continued

Now that you've generated the toolpath, you'll notice that it's not particularly efficient. It machines the air for a while before entering material.

1) Right click 2D Pocket 1, and choose Edit.

2) Click on the Heights tab.

3) Change the Top Height to Selected Contours.

You'll notice there's no prompt for you to select a contour. Selected Contours refers to the contour(s) you selected in the Geometry tab, which you know is the bottom contour of the hole.

4) Change the Top Height Offset to 0.5.

This offsets the top height to 0.5" above the selected contour. When you view the spoon from the side, you'll notice that the top and bottom height rectangles (dark and light blue, respectively) do not appear. This is annoying, but it only happens when you choose Selected Contour. In real life, when you're not following an Instructable, you may have to do several trial-and-error attempts to get the height offset correct.

5) Click OK to generate the toolpath. You can immediately see that it's much more efficient now.

6) To show you a way to address the issue in Step 4 of not being able to view top and bottom heights, here is another way to set heights. Right click Pocket 1 and choose Edit. In the Heights tab, for Top Height, choose Stock top with an Offset of -0.6. The light blue rectangle corresponding to the top height appears on the screen. You can see that it lies above the top of the hole in the handle. Now change Bottom height to Model bottom. Play around with the offset number until the dark blue Bottom Height rectangle gets close to the bottom of the hole. I chose 0.35. Now hit OK to generate the toolpath.

You'll see that the toolpath is basically the same as it was in Step 5. This just shows you that there is more than one way to tackle the same problem in CAM.

Step 14: Simulate!

1) Click Setup 1.

You want to get in the habit of selecting Setup before clicking Simulate to simulate all the toolpaths you've created. Even if you're not reviewing earlier toolpaths, you need to see how the latest one you created interacts with the surfaces you've already machined. If you don't click Setup, the CAM software will only simulate the toolpath you just created. Viewing it in isolation is not useful.

2) In the ribbbon, choose Simulate.

3) Ensuring that the Toolpath Mode is still Tail, and Stock is still checked, watch the simulation carefully. Note that both toolpaths appear in the timeline below the control buttons.

4) You'll notice that it's hard to see the end of the Pocket toolpath. In the dropdown next to Tool, choose Flute. This turns off the visibility of the shaft and holder so you can see the bottom of this toolpath. Making the stock transparent and viewing the simulation from the side view may also be useful.

Step 15: Parallel Finishing

Now that you've roughed the spoon and machined the hole in the handle, it's time for finishing.

1) In the ribbon, choose 3D>Parallel.

The popup defines Parallel:

"A widely used finishing strategy, the passes are parallel in the XY plane and follow the surface in the Z-direction. You can choose the angle as well as the stepover in the horizontal direction...Parallel finishing passes are best suited for shallow areas and can be confined to machine only up to a given contact angle."

2) Click Select next to Tool, and choose 1/2" Ball (1/2" Ball EM Short). Click OK.

Always use ball nose endmills for 3D finishing, because the radius on the end of the tool will give you a smooth, precise finish. The larger the diameter of the ball nose, the better the surface finish, because the cusps (scallops) between each pass are more shallow and therefore more difficult to visually detect. The only reason to choose a smaller diameter ball nose is to reach tighter crevices or smaller details.

3) Click on the Geometry tab.

4) Note that by default, the geometry of this toolpath will follow the silhouette of the model. You don't want to finish the stock that the spoon tabs are attached to. In the dropdown next to Machining Boundary, choose Selection.

5) Look at the model from the side. Carefully select the contour that runs along the side of the spoon, as shown in the attached screenshot. The toolpath boundary will appear as a green contour.

If you make a mistake and select the wrong contour, press the "X" next to "Chain" by the Machining Boundary Selection and start again.

6) Next to Tool Containment, select Tool Outside Boundary. This will ensure that the tool machines along the sides of the model--not just its top surface.

7) Click on the Passes tab.

8) Change Stepover to 0.03. The smaller this number, the finer the surface finish.

9) Click OK to generate the toolpath.

Step 16: Parallel Finishing Continued

If you view this toolpath from the side, you can already see the bottom height is unnecessarily low. You only need this toolpath to go to the bottom of the edge of the model.

1) Right click Parallel 1, and choose Edit.

2) In the Heights tab, in Bottom Height, change the Offset to 0.3.

3) Click OK to generate toolpath.

Step 17: Simulation Crash!

1) Click Setup 1.

2) In the ribbon, click Simulate.

3) Something is going wrong! When the tool turns red and red dashes appear in the timeline, this indicates a Simulation Crash or Collision. If you hover your mouse over one of the red dashes in the timeline, you'll see that the collision is labeled "Shaft collides with stock."

There are three types of simulation crashes:

-Shaft collides with stock: The tool is trying to cut beyond the length of its cutting flutes. Increase your bottom height or choose a longer tool.

-Holder collides with stock: The holder of the tool is hitting stock. Change your heights or machining boundaries.

-Rapid collision with stock: The tool is trying to move through stock at rapid speed. Check your lead-in and lead-out parameters.

Use the view cube to view the spoon from the side during a collision. You can see that this tool is too short to handle cuts of this depth. You will need to choose a longer tool in your next edit, but for now, analyze what's here.

4) Looking at the simulation controls, click the "Go to End of Toolpath" button, three over from the Play button. You'll notice that the model is interfering with the view of the stock. In the CAM Feature Tree, click the light bulb next to "DMS_spoon_certification_part." It will turn off the visibility of the model.

5) You'll notice that the top of the spoon looks nice and smooth, but the sides of the spoon are pretty rough. You'll need another finishing strategy to tackle the sides of the spoon, because Parallel doesn't produce a good finish for steep walls.

Step 18: Notes on Simulation Crashes

Let's pause for a moment to go into greater detail about simulation crashes, so that you understand how they work before moving on.

-No collisions will be detected with non-library tools. The tools in the DMS library have their flute length, body length, and holder modeled for you, to give you very accurate collision data. This is not the case for any custom tool, such as drills, and you will need to manually measure your tool against the heights in your toolpath.

-CAM simulation will not tell you if you're being too aggressive. For example, you could have an optimal load set to 100% of your tool diameter, and the simulation will not show any issues. However, you know that the optimal load should not be greater than 50% of the tool diameter without damaging the tool or ripping up the stock.

-CAM software does not include collisions with fixtures by default. If you're planning to use clamps on the corners of your stock, for instance, you'll need to keep this in mind when toolpathing, or even better, model the clamps yourself and choose them as Fixtures in your Setup.

Step 19: Switching Tool and Editing Tool Number

Back to the spoon. Turn its visibility back on in the CAM Feature Tree.

1) Right click Parallel1 and choose Edit.

2) Choose Select next to Tool, and choose 1/2" Ball (1/2" Ball EM Long). Click OK.

3) While still in the Tool tab, notice that the tool is labeled #4.

On the left side of the screen, in the CAM Feature Tree, notice that the tools for Adaptive1 and 2DPocket1 are labeled T1 and T2, respectively. The CAM software automatically adds another number to the tool number each time you select a new tool.

When doing CAM for the DMS, you want to ensure that your tools are numbered in chronological order. When you post process your program, this tool number will be the label for that tool in the G-code. When you insert tools into the machine, you will assign them the same number. The DMS will keep track of each tool by number, and when it's not using a tool, it will store it in its numbered slot in the magazine behind the machine.

To keep yourself organized, you want to make sure your tools don't skip numbers or go in non-sequential order in the CAM software. It would be easy to accidentally label a tool #3 if it's the third tool you insert into the DMS, but if the G-code refers to it as T4 (tool 4), the DMS will either throw an error or grab the wrong tool.

In other words, you need to change your tool number to #3.

4) Click Select next to Tool again.

5) Right click Tool #4, 1/2" Ball EM Long, at the top of the window under DMS_spoon_certification_part, and choose Edit. DO NOT edit the tools in the DMS tool library!

6) In the window, click the Post Processor tab.

7) Change Number to 3. The Length and Diameter offset should automatically switch to 3 as well.

8) Click OK.

9) The CAM will give you a pop-up window every time you change a tool number, but it's fine to do this override. Click Yes.

10) Now you'll see the 1/2" Ball EM Long under DMS_spoon_certification_part, but it's now labeled #3. Select it and click OK.

11) Confirm in the Tool tab that the tool is now #3. Don't generate the toolpath yet.

Now you know how to edit tool numbers. For your own DMS CAM programs, it is a good practice to wait until you're done with CAM and have simulated multiple times before editing the numbers. This will save you some time because you never know when you're going to change a tool, rearrange the order of toolpaths, etc.

Step 20: Parallel Toolpath Editing

You'll want to make a few more changes before generating the toolpath.

1) Click the Passes tab.

2) Check the box next to Stock to Leave.

3) Change Radial Stock to Leave to 0.01. Make sure Axial Stock to Leave is still 0.

Axial Stock to Leave is the amount to leave along the tool axis--that is, on the top or bottom of the part.

Radial Stock to Leave is the amount to leave perpendicular to the tool axis--that is, on the walls of the part. By default, the radial stock to leave follows the set axial stock to leave.

By leaving some radial stock behind, you just ensured that the tool leaves some material on the sides of the spoon model. You'll be finishing those with another toolpath that is better for steep walls. If you didn't leave stock behind, the finishing toolpath might not smooth out the rough edges caused by this Parallel toolpath.

Note: If you ever need to machine into your model, you can set Stock to Leave to negative numbers.

4) Click OK to generate the toolpath.

5) Click Setup 1.

6) In the ribbon, click Simulate.

7) Turn off the visibility of the solid model so it doesn't interfere with the stock, and inspect. There are no more collisions, the top of the spoon looks good, and you're correctly prepared the stock for finishing the steep walls.

Step 21: 3D Contour

To address the steep walls, you will use a strategy called 3D Contour.

1) In the ribbon, click 3D>Contour. The pop-up defines Contour:

"This is the best strategy for finishing steep walls, but can be used for semi-finish and finish machining on the more vertical areas of a part.

If a slope angle is specified, for example 30 degrees to 90 degrees, the steeper areas are machined, leaving the shallower areas up to 30 degrees for more appropriate strategies."

2) Notice the last tool you used is selected by default. This is what you want, so click the Geometry tab.

3) Next to Machining Boundary, choose Selection.

4) Carefully click on the same contour you selected for the Parallel toolpath, that runs around the edge of the spoon.

5) Next to Tool Containment, choose Tool Outside Boundary, with an Additional Offset of 0.25. This will allow the tool to enter into the toolpath from the sides, rather than from the top.

6) Check the box next to Slope. You are going to constrain the toolpath to the steeper areas, as mentioned in the definition of the Contour toolpath.

7) Change From Slope Angle to 65 degrees.

8) Click OK to generate toolpath.

Look at the Contour toolpath. Notice that by default, the tool will helix to lead into the toolpath. You've already machined this area, so you'll want to edit this toolpath, change your heights, and remove the helix. You'll learn how to do this in the next step.

Step 22: 3D Contour Editing

1) Right click Contour1 and choose Edit.

2) Click on the Heights tab.

3) Viewing the spoon from the side, under Top Height, enter an Offset of -0.4. This will offset the top height 0.4" below the top of the stock. You can see the light blue line corresponding to top height just above the top edge of the spoon.

4) Under Bottom Height, enter an Offset of 0.3. This will offset the bottom height 0.3" above the model bottom. You can see the dark blue line corresponding to bottom height just touching the lowest part of the bottom edge of the spoon.

5) Click the Linking tab.

6) Under Ramp, change Ramp Type to Profile. Hover your mouse to read about the ramp types. Profile ramps follow the profile of your part. This will save time and make a smoother toolpath.

7) Click OK to generate toolpath.

Step 23: Simulation Crash and Correction

1) Click Setup 1.

2) In the ribbon, click Simulate.

3) Press Play.

Looks like there's another collision--Rapid Collision with Stock. This sometimes happens in 3D toolpathing when the tool is first descending into a toolpath, as it is here. This means that the tool is moving at rapid speed at a Z-height that is too close to your stock, or even within your stock.

4) Close the simulation, and inspect the toolpath from the side by clicking on Contour1 in the CAM Feature Tree on the left.

Look especially where the tool enters material. Remember the color codes for the different parts of the toolpath:

Blue = The toolpath itself. The tool moves at the cutting feedrate.

Yellow = Positioning moves. The tool moves at rapid or high speed.

Green = Lead-in/lead-out. This is how the tool moves right before or after each cutting move.

You'll notice that the tool moves along the yellow line, at rapid speed, at a height that's just slightly above toolpath itself, meaning that your tool is moving too fast into stock. The green line--the lead-in--needs to be elevated higher so that the tool slows down before cutting. During the lead-in, the tool moves at the lead-in rate, which is much slower than the rapid speed.

5) Right click Contour1, and choose Edit.

6) Click on the Linking tab.

7) Change Safe Distance to 0.2.

Safe Distance is the minimum distance between the tool and the part surface during positioning moves. This prevents the tool from moving at rapid speed too close to the part. When you increase Safe Distance, the size of your green lead-ins also increases.

Usually, the default Safe Distance setting is good enough and can be left alone, but with more complex 3D parts, there is more likelihood that the Safe Distance needs to be changed to a more conservative number.

8) Click OK to generate toolpath.

9) Inspect the toolpath from the side again. Note that the green lead-in now begins higher up in Z. There is also now a series of red ramps that slow the tool down as it moves laterally towards the part.

10) Click Setup 1 and then Simulate.

11) Confirm that there are no more collisions. The 3D Contour has nicely finished the sides of the spoon. Close out of the simulation.

Step 24: Drill Registration Holes

You're almost finished with this side, but you need to drill three registration holes in your part that will go through the material and then down into your spoiler board. This way, when you flip your part, you can insert dowels through the holes and into the spoiler board that will align your part perfectly with Setup 1. This will prevent you from having to change the X and Y values of your WCS after the flip.

If you didn't have a registration system, you'd have to reset the WCS after the flip in X, Y, and Z. Remember that the DMS does not have a Renishaw probe to locate your part: you have to do this "by eye" by jogging an endmill or tool as close to Work Home as possible. Even if your stock is exactly square and positioned perfectly square to the machine, it would still be nearly impossible for you to set the WCS "by eye" and get the two sides to align perfectly with one another.

1) In the ribbon, click Drilling.

2) Next to Tool, click Select.

3) In the Sample-Aluminum library, choose the 1/2" drill. Click OK.

4) Change the Spindle Speed to 1000 rpm.

You must manually set feeds & speeds because this tool is not in the Pier 9 CNC Tool Library. By default, drill rpm is not correct. Use the following schedule for Sample Library drills:

1/8" Drill: 4000 rpm

1/4" Drill: 3000 rpm

3/8" Drill: 2000 rpm

1/2" Drill: 1000 rpm

5) Click the Geometry tab.

6) Select the bodies of the three holes.

7) Click the Heights tab.

8) Under Bottom Height, check Drill Tip Through Bottom.

Remember that a standard drill bit has a 118 degree angle at the end. By default, the toolpath will end exactly at the tip of the drill. In this case, this means the drill would not go all the way through the stock.

9) Add a Break-Through Depth of 0.35.

The break-through depth specifies how much further the tool drills past the bottom of the hole, AFTER it has broken through. The tool will drill 0.35" past the break-through, into the spoiler board. You want this so the dowels will have a place to be seated after the flip. However, you have to be very careful that you don't drill through your spoiler board, into the acrylic on the machine bed of the DMS. The tip of this drill bit will go 0.5" into the spoiler board, so your spoiler board MUST be at least 3/4" in depth.

10) Click the Cycle tab (far right).

11) Change the Cycle type to Deep Drilling-Full Retract. Though new fields will appear, leave those at the default settings.

The default drilling cycle is Drilling-rapid out. This brings the tool into the hole once and then rapid retracts. This is fine for shallow holes, but could break drills in deeper holes.

Deep Drilling is the best cycle for drilling holes with depths of more than three or four times the tool diameter, by periodically retracting the tool out of the hole to allow chips to escape. Your drill depth is 1.5" (depth of stock) plus 0.5" (depth into spoiler board). 2/0.5 is 4, so you should use Deep Drilling. If you're ever not sure what drilling cycle to use, just use Deep Drilling--it's conservative and will help drill bits last longer.

12) Click OK to generate toolpath.

13) Click Setup 1.

14) Click Simulate. Turn off the visibility of the model and make the stock transparent so you can watch the deep drilling.

Step 25: Flip the Part

You've finished Setup 1! Anytime you move a part in the machine or reset your WCS, you need to create a new Setup.

1) Click Setup 1 so the stock and WCS appear, and then carefully flip the spoon in the view window by orbiting or clicking the corner of the View Cube where Top, Back, and Right intersect. The WCS should now appear in the front bottom left corner.

You've just flipped the part away from you. You want to make sure you're doing this correctly because of the way the registration holes are designed. For instance, if you accidentally flipped the part sideways (with the head of the spoon on the left side)--either in the CAM software or in real life when you get to the DMS--your registration holes would not align with the holes in the spoiler board.

2) Right click the Home icon next to the View Cube>Set current view as Home>Fixed distance.

3) Click Setup in the ribbon.

4) Click the top back left corner node to reposition the WCS.

You are not obeying the right hand rule. You need to flip the Z-axis.

5) To flip the Z axis, click the head of the Z arrow.

6) Click the Stock tab.

7) Change Mode to Fixed Size Box.

8) Click the Post Process tab.

9) Change the program number to 100002.

The DMS only accepts six-digit numbers, and it's a good system to align program numbers with setup numbers. That is: Setup 1, 100001. Setup 2, 100002, etc.

10) Click OK to generate Setup 2.

11) Hover your mouse over Setup 2, and notice that there's a black dot that says "Activate Setup/Folder." This means that Setup 2 is your active setup, and any new toolpaths you create will go into this setup.

Step 26: 3D Adaptive Roughing

1) In the ribbon, choose 3D>Adaptive Clearing.

Just as you did on the first side, you want to start by roughing.

2) Click Select next to Tool.

3) Choose the 1" Bull Nose Rough Short, Tool 1. Click OK.

Because this is the first tool you use in Setup 1, leave the tool number at 1.

4) While still in the tool tab, set Coolant to Flood.

You want the dust collection system closed during this roughing operation because it will create a lot of chips, and the tool is long enough that the dust collection won't interfere with the stock.

5) Click the Geometry tab.

6) Next to Machining Boundary, choose Selection.

7) Select the same contour that you chose for the Parallel toolpath in Setup 1--the one that runs around the side of the spoon. A green silhouette will appear (see isometric and side views in the attached images).

By default, Adaptive will remove all the stock that it can reach. In Setup 1 you already removed almost all the stock you need to get rid of, other than the material inside this contour. Selecting this contour will make the toolpath much more efficient. Confirm that the Tool Containment is Tool outside boundary, with an Additional Offset of 0.

8) Uncheck Rest machining.

It's easier to constrain this toolpath with a selection in the Geometry tab, rather than relying on Rest machining, which can take a prohibitively long time to process and gives you less control.

9) Click the Heights tab.

10) Add a Bottom Height offset of 0.75.

If you look at the top of this spoon as an S-curve, you only need to machine to the bottom of the S.

11) Click the Passes tab.

12) Change Optimal Load to 0.2.

In Setup 1, for Adaptive roughing you chose an Optimal Load of 0.3". However, now the spoon has much less support and is more prone to chatter. It's important to be more conservative now, using 20% of the tool diameter.

13) Change Maximum Roughing stepdown to 0.4.

In Setup 1, your Adaptive stepdown was 50% of the tool diameter (0.5"), but again, you are being more conservative this time by only using 40% of the tool diameter.

14) Click OK to generate toolpath.

Step 27: Simulate!

1) Click Setups (above Setup 1), or click Setup 1, Shift, Setup 2 to select both.

2) In the ribbon, click Simulate.

It's important to always simulate all setups, so that you can see what your stock actually looks like at any given time.

3) Inspect the part. Notice the area around the head of the spoon need some attention. Keep the model visible, make the stock transparent, and view from the side. There's too much stock still here to go right to finishing.

Step 28: Sketch Bounding Box

A useful way to machine that area around the head of the spoon is to use a bounding box to constrain the toolpath.

1) In the ribbon, change the Workspace to Sculpt.

2) Right click the face of the stock next to the spoon head, and choose Create Sketch.

3) In the Sketch dropdown, choose Rectangle>2-Point rectangle.

4) Draw the rectangle so that its left side aligns with the rectangular prism of stock, and its right side almost extends to the full width of the spoon scoop.

4) In the ribbon, click Stop Sketch.

Step 29: Second 3D Adaptive Roughing

1) In the ribbon, change the Workspace back to CAM.

2) Because you changed something in the Sculpt workspace, you need to regenerate toolpaths. Right click Setup 1, choose Generate Toolpaths. Do the same for Setup 2.

3) In the ribbon, choose 3D>Adaptive Clearing.

4) Next to Tool, click Select.

5) Clear the filters at the top.

6) In the DMS tool library, choose the 12mm flat (12mm EM Long) tool.

7) Click OK, and ensure in the Tool tab that this tool is labeled #5. If it isn't, you know how to edit a tool number.

8) Click the Geometry tab.

9) Next to Machining Boundary, click Selection.

10) Choose the rectangle that you just created in the sketch. Ensure Tool Containment is Tool outside boundary.

12) Uncheck Rest machining.

Again, you are doing Rest manually by setting your own constraints for this toolpath.

13) Click the Heights tab.

14) Add a Top Height offset of -0.5.

15) Add a Bottom Height offset of 0.5.

These values set the upper and lower bounds of this toolpath, which roughly correspond to the areas of the stock that were left behind in the previous operation.

16) Click the Passes tab.

17) Change Optimal Load to 0.1.

A 12 mm tool is close to 0.5" in diameter. For roughing in the last operation, you chose an Optimal Load of 20% tool diameter. 0.5" x 0.2 = 0.1"

18) Change Maximum Roughing Stepdown to 0.15.

The maximum stepdown is 0.25" for this tool, but this tool is quite long, which makes it more flexible and therefore more prone to stress. You also know that this whole setup is more fragile than the first side, so it makes sense to be conservative with this.

19) Click OK to generate toolpath.

Step 30: Simulate!

1) In the ribbon, go into the Sculpt workspace and turn off the visibility of the sketch by expanding Sketches and clicking the light bulb next to Sketch2.

2) Go back to the CAM workspace.

3) Click Setups.

4) In the ribbon, click Simulate.

This toolpath took away the low area we were concerned about, around the head of the spoon. There is a large "step" between this toolpath and the previous toolpath, but it's not large enough that the finishing can't handle it.

Step 31: Parallel Finishing

1) In the ribbon, click 3D>Parallel.

2) Click Select next to Tool.

3) Choose Tool #3, 1/2" ball (1/2" Ball EM Long). Click OK.

4) Click on the Geometry tab.

5) Next to Machining Boundary, choose Selection.

6) Carefully select the contour that runs around the edge of the spoon--the same one you chose in the Parallel toolpath in Setup 1, and as a boundary for the first Adaptive Clearing toolpath in Setup 2.

7) Verify that Tool Containment is set to Tool Center on Boundary, and add an Additional Offset of 0.2.

This will allow the center of the tool to move slightly outside the boundary, to ensure that it reaches the entire fillet around the top edge.

8) Click on the Passes tab.

9) Change the stepover to 0.03.

This ensures that the parallel finishing on both sides will be visually consistent.

10) Click on the Linking tab.

11) Change the Safe Distance to 0.2.

12) Click OK to generate toolpath.

Step 32: Simulate!

1) Click Setups in the CAM Feature Tree.

2) Click Simulate in the Ribbon, and turn off the model visibility.

3) Click >| to skip to the final CNC machined part.

4) Inspect the model.

This is what the part will look like after all machining operations. Zoom into the various parts and make sure they look the way you expect.

Step 33: Optional: Save Stock As .stl

At any point in your simulation, you can save your machined stock as an .stl file.

1) Right click on your machined stock.

2) Choose Stock>Save Stock.

3) Save your stock as an .stl file.

You know there is a difference between the model and the machined material. You can use this mesh model of the machined material if you have another component to your piece that you want to 3D print, for instance, if you're making a press fit lid for a cavity.

Step 34: Generate Setup Sheets

Setup Sheets summarize all the toolpaths in your setup, including tools, operations, and speeds and feeds. They also contain the comments for each tool, which are important for the DMS because they show you which number each tool corresponds to in the DMS library. Use setup sheets as a checklist while setting up your material inside the machine, loading tools, and removing your part from the machine. Print them out and use them to take notes as you go.

NOTE: If you haven't cut the wood for your stock yet, you'll come back to this step and the next step (Post process) after updating your setups with actual dimensions. Read through the steps just so you understand them, and then come back when you're ready.

1) In the CAM Feature Tree, click Setup 1.

2) Ensure that your window displays the part from a "tool isometric" view for Setup 1. This means the Work Coordinate System obeys the right hand rule and appears in the top back left corner of your part. You are viewing the part from the same perspective that it will appear in the machine during Setup 1.

3) In the CAM Feature Tree, right click Setup 1, and choose Setup Sheet.

4) Open a folder to save the Setup Sheet.

5) Once the setup sheet opens in the browser, print a hard copy. Reference the above screenshots of Setup Sheets to ensure that yours match.

6) Ensure that your window displays the part from a "tool isometric" view for Setup 2.

7) In the CAM Feature Tree, right click Setup 2, and choose Setup Sheet.

8) Open a folder to save the Setup Sheet.

9) Once the Setup Sheet opens in the browser, print a hard copy.

Step 35: Post Process

Now that you've generated setup sheets, it's time to post process to convert your CAM file into G-code. G-code is the computer language that CNC machines use to execute your program. Each line is a a different instruction for the machine.

Note: If you're on a Mac, your post process window will look different from my screenshots. To download the DMS post processor and access it on a Mac, first download the DMS fagor post processor attached at the bottom of this step, DMS fagor 8055i M5xS_R8.cps, and save it to your desktop. Then, follow this Adding personal post processors in Fusion 360 forum. Scroll down to the middle of the page to access instructions for a Mac.

If you're on a PC, proceed here.

1) Download the DMS fagor post processor attached at the bottom of this step, DMS fagor 8055i M5xS_R8.cps. Save it in a folder called Custom Post Processors. This is the same DMS post processor found in the Pier 9 CNC Tool Library Instructable.

2) Right click Setup 1.

3) Choose post process.

4) Under configuration folder, click the three dots on the right side. Find and select the Custom Post Processors folder you just made. You won't see anything inside this folder, but don't worry: you're just mapping its location. Click Open.

5) In the dropdown under Post Configuration, choose DMS fagor 8055i M5xS_R8.cps.

6) Insert your USB into your computer, and then click the three dots on the right under Output Folder.

7) Find your USB drive, and click Open.

8) Verify your program number contains six digits.

9) Under Program comment, write something useful like "DMS cert part setup 1".

10) Click Post.

11) View the G-code in the editor. These are the instructions for setup 1.

12) Repeat steps 2-10 for Setup 2.

Congratulations! You've successfully worked through the CAM for an organic 3D part with a flip. Now that you have your setup sheets and G-code, it's time to start machining.

Go to the next Instructable in this series: