Introduction: Gameboy Advance: Tingle Tuner [Wind Waker]

The Gameboy Advance: my favorite handheld of all time and a staple of the Nintendo franchise; The perfect side piece to the GameCube. It's crazy to think it's pushing 2 decades and recently, I had a hankering to delve into my old games and along the way, I discovered that the custom console scene is rife with creative people making mods, shells and custom parts.

I never expected to get bit by the custom console bug but a few weeks later, I went a little overboard and built a gameboy I wish existed 18 years ago: The Tingle Tuner from 'The Legend of Zelda: Wind Waker.'

For those uninitiated, the Tingle Tuner was an in-game item (and somewhat lore-breaking) that allowed GBA connectivity through a cable that connected to the GameCube to aid Link in dungeons and alter a few in-game interactions, and while this tingle tuner mod doesn't have a cable (yet), it has a wireless link cable adapter built in! (Tbh, I'm surprised I haven't seen anyone else before build this!)

This instructable will document the tingle tuner attachment itself and the custom GBA with its mods.

Step 1: The Supplies

The supplies vary on what you want out of this build, whether it's for the tingle tuner attachment, the GBA, and any mods to choose to apply.

The Tingle Tuner Attachment:

- Gameboy Advance Wireless Adapter

- 3D printer (I used an FDM machine)

- Sandpaper/Epoxy clay

- 22 gauge wire

- 25mm acrylic ball

- tap wrench + M3 tap|screws + Drill (Optional)

- Spray Paint + Primer

The Gameboy Advance:

- A 2nd hand GBA

- IPS V2 LCD Screen + Precut shell (also comes with complete set of buttons, glass screen, membranes, screws, sticker and respective screwdrivers) AliExpress

- Spray Paint + Primer

- Yellow Button Start/Select Membrane

- Soldering Iron (Optional)

Step 2: Tingle Tuner Attachment

Included is a Thingiverse link to the 3D files. I did a few alterations to get a perfect fit with no interference. Included is a 'solid' version if you're not using a wireless adapter.

The main model comes in two halves and have been positioned to take advantage of printing the inside on a flat plane. This requires cleanup after removing supports on the outside but easily fixed with Epoxy clay. (Black Milliput)

Using Ultimaker Cura with an FDM printer using PLA, I recommend printing at full infill, at the finest micron my printer can do with supports, Ironing enabled (Zig Zag) and randomized Z seam alignment. This will make your internals ultra smooth, crisp and will allow the wireless adapter board to slot straight in. An even cleaner print can be done with a 0.25 nozzle, I only have 0.4.

Note: If you have access to a resin SLA printer (AnyCubic Photon, Elegoo Mars, Form 2 etc) you can achieve a superior print all around with less support material hassle.

A 2.0mm tri wing screwdriver is required to unscrew the wireless adapter (included with the ips v2 screen + shell kit but can also be bought separately cheap)

The two halves fit snug when pressed together but for assurance, I allowed for a tap hole to thread in an M3 screw on the back to clamp the parts shut. The holes need reaming out with a 2.5mm drill bit and tapped with an M3 tap.

I used spray primer to clean up and check for imperfections in my Milliput, it's important to get this flawless; any scuffs will show up in the final product.

Step 3: Battery Mod

A popular option for those who mod their screen is LiPo batteries with a custom board. These are wonderful batteries but cost a pretty penny. Here's a link: https://retrosix.co.uk/CleanJuice-USB-C-Battery-Pa...

However, my alternative is these Xbox One Venom rechargeable batteries. They're NiMh batteries and they come in twin packs (for a third of the price of one LiPo battery) and do the job well. I came across an Imgur post detailing this and used it on my own, minus the spring.

Two modifications need doing: the batteries and the case, all can be done with a pair of plastic cutters. On the battery, cut the plastic tab and pull up the positive contact. To be on the safe side, tape the contacts when cutting. Bridging the contacts with a metal cutter seems less than ideal -_-

The case needs the battery contacts pulled out and plastic trimmed to fit the battery. It's uncanny how well it fits...

Conveniently, if you decide to splurge on a LiPo battery, the shell is trimmed exactly the same way and it drops right in. If you want to use regular batteries again, just add the battery contact back into its slot.

The downside of this battery is the battery cover needs to be trimmed to allow space for the charger but as a bonus you can charge the battery directly in the GBA, a pro and a con.

Step 4: Tingle Tuner Paint

Before paint, ensure your print is flawless: Use Milliput, model filler and sandpaper to achieve the finish. When it's ready for paint, mask the inside of the prints as close to the edge as you can; use a scalpel to get a clean edge.

For mounting I used double sided tape and a popsicle stick pressed firmly.

Primer first, then a gloss white base coat and finally, green. If you notice any blemishes at any stage, clean up and respray. Most importantly, let it dry fully.

Step 5: Buttons + Paint

My original plan was to use pre-made aftermarket yellow buttons, however mine were less than impressive so I opted to use the buttons that came with my shell; a bonus to this is these buttons fit perfectly with the shell to begin with.

Key the surface with something like scotch brite, a brillo pad or very fine sandpaper, (at least 600) this helps paint bond. Mask around the buttons that aren't seen through the shell (this prevents unnecessary build up) and degrease with lighter fluid, ready for paint. These are mounted on sticks, just like the print.

Primer, white gloss and gloss yellow on top. To protect the paint, I used a 1K lacquer (very thin, very strong, very fast drying)

For the ball that hangs from the tingle tuner, I opted for a 25mm acrylic ball and 22 gauge yellow wire. A hole is drilled in the acrylic ball that matches the wire, superglued in and keyed, painted and lacquered just like the buttons.

Just for looks I dry fitted the buttons into the raw shell and was pretty darn happy with how they turned out.

Step 6: Case Paint

NOTE: If you're planning to use an LCD screen on your Gameboy Advance with an uncut shell, refer to the next step and look at the guides on how to cut the shell for the screen before painting. In my case, my shell was ordered precut with the kit.

Like the tingle tuner head and the buttons, the shell needs keying and masking for paint. I used the spare plastic screen the LCD kit comes with to mask the front, the battery cover to mask the back and I masked the edges to prevent build up.

Primer, gloss white and green. I had the opportunity to use 2K lacquer on these parts but the same lacquer used on the buttons works just as well, however this 2K lacquer I used has a lustrous thick shine. Allow to cure fully before handling; if in doubt when handling, leave it another day, you don't want thumbprints!

For reference, My green is Pantome 348c and my yellow is Pantome 108c for colour matching.

Step 7: LCD Screen (Optional)

The LCD kit I bought comes with the screen and ribbon, as well as the modified shell, buttons, screws + screwdrivers, back sticker, glass screen lens, membranes, battery cover, precut adhesives; an entire GBA minus the motherboard. The precut shell allows for space for the screen to be placed. This can be done yourself on an original shell following a guide but the precut shell + parts are so cheap it's silly not to.

Links for kits: AliExpressFunnyPlayingRetroSix I opted for the AliExpress kit (similar ones on eBay) purely for cost effectiveness.

There's 2 installations: solderless or soldered. The kit can be dropped in without soldering with a set screen brightness, or it can be soldered to have brightness control through the bumpers. Installation also varies on pin count, 32 or 40. Check your boards pin count by comparing the original screen ribbon cable to the kit cable (the widths will match) Mine is a 40 pin, if yours is 32, check this guide here to fold it accordingly. I'm also including a visual guide here to cover all basis.

Lastly I recommend 3D printing this IPS bracket with PLA or ABS to center your screen. The bracket may need light sanding and filing to fit comfortably if you bought a kit; avoid a snug fit as the screen is fragile.

Now for the Install:

- Fit the screen into the GBA, preferably with the bracket (spend the time to get the best fit with files and sandpaper) Kits tend to come with an insulating film; I recommend applying this to the back.

- Carefully rotate the GBA and stick the glass screen on the face of the GBA.

- Rotate back and apply solder to the back of the ribbon labelled 'SEL' 'R' and 'L'. Disregard 'GND'

- Solder thin wire to these points. I chose yellow for 'SEL', red for 'R' and black for 'L'

- On the face of the motherboard, locate 'TP2' shown in the image and apply solder

- Solder the 'SEL' wire to that point

- Assemble all buttons and screw in the motherboard' tuck the 'SEL' wire

- Locate the 2nd pin on each bumper imaged above and solder your 'R' and 'L' wire accordingly.

At this stage the unit can be screwed together with the final touch of the back sticker; most kits come with one.

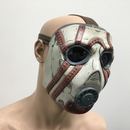

Step 8: Kooloo-Limpah

Even without the attachment, The green GBA on its own is an absolute beauty. I've put a good 50 hours on it and it looks and feels like a legit limited edition gameboy; it's a shame Nintendo never did anything quite like this.

The attachment when plugged in feels as natural as a gameboy without it. It's light, non intrusive and doesn't feel out of place when playing on it. As you would expect, the wireless adapter has all the regular functionality. It looks fantastic on a shelf and is sure to catch an eye.

If there's interest in the future, I can see about making a corded version from an official gamecube link cable so you can actually use the tingle tuner on your tingle tuner when playing Wind Waker.